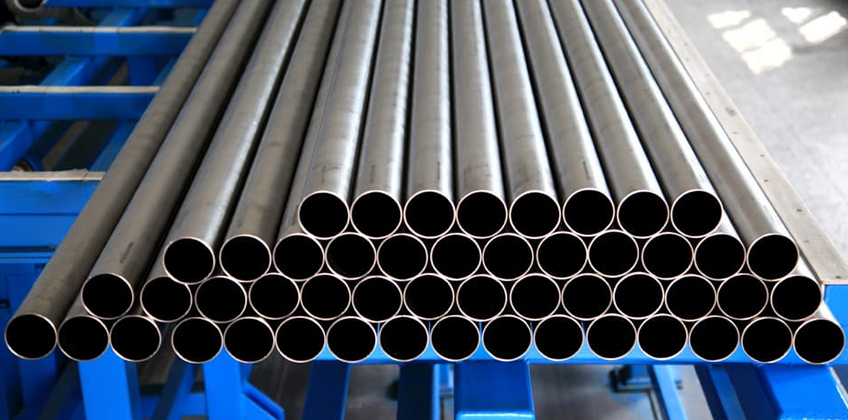

Inconel 625 is a nickel-chromium-molybdenum alloy with excellent strength and corrosion resistance at high temperatures. It is often used in applications where extreme environments such as high temperatures, aggressive chemicals, and seawater are present. Inconel 625 tubes and pipes are one of the most common forms of this alloy used in various industries.

Properties of Inconel 625:

- High resistance to corrosion and oxidation

- High strength and toughness at elevated temperatures

- Excellent resistance to chloride stress-corrosion cracking

- Good fatigue resistance

- Non-magnetic

- Good weldability

Applications of Inconel 625 pipes and tubes:

- Oil and gas industry: Inconel 625 is commonly used for oil and gas extraction and production due to its high resistance to sour gas, seawater corrosion, and pitting.

- Aerospace industry: Inconel 625 is used for engine components, exhaust systems, and other high-temperature applications in the aerospace industry due to its high strength and heat resistance.

- Chemical processing industry: Inconel 625 is used in various chemical processing applications such as heat exchangers, piping systems, and reactors due to its high resistance to corrosion and oxidation.

- Marine industry: Inconel 625 is used in seawater applications due to its high resistance to corrosion and pitting.

In conclusion, Inconel 625 pipes and tubes are a popular choice for high-temperature and high-corrosion applications in various industries. Its unique properties make it suitable for use in harsh environments where other materials may fail.